|

|

|

I am now about to delve into the ‘murky’ world of Australian Ford engines. I am going to say up front that the information here has been gleaned from some years of following the Falcon GT scene through the Falcon GT Club of Australia to whose members I gratefully acknowledge their assistance and wisdom. Mistakes that appear here are most probably the result of me misinterpreting what I have been told or read. If there is anything glaringly wrong, please get in touch and point out my mistakes and I will correct it. |

|||||||||||||||

|

With the above in mind, I make no apology with starting off with the 351 ci Cleveland engine, as fitted most effectively to the Falcon GTs, but which also survived until 1982, Australian built and powering Australian Fords of many types. While the U.S. version of the 351C existed in factory vehicle production for only 5 years - 1970 to 1974 - the Australian ‘version’ ran from 1972 to 1982, nearly three times as long, and as such the Cleveland could be regarded as more Australian than American. Its popularity down under has spawned a thriving industry of tuners, machinists and performance parts suppliers providing many services at reasonable cost in comparison with those in the U.S. where the 351C is regarded as ‘rare’ and ‘exotic’ and the willingness of suppliers to provide support and parts is thus restricted by the engine’s perceived rarity, especially when compared with its Windsor equivalent, an engine that has a long history in the U.S. bringing availability, ubiquity and cheapness to the forefront. |

|||||||||||||||

|

351 Cleveland |

|||||||||||||||

|

Let’s start with a general overview, specifically an aid in identifying the Cleveland engine. Before the 351C, there was the 351W which was a 351ci capacity version of the original Windsor engine family - so-called because that is where the original engine factory was, Windsor, Ontario - which started life as a 221ci in 1962, but grew to encompass the famous 289 and 302ci versions through the sixties. |

|||||||||||||||

|

In these small capacity displacements, the 289/302 was a great little engine - and it went on to become even greater in the eighties and nineties - but as car size increased in the U.S. Ford decided that they needed larger capacity from the small block to generate more torque to move the heavier cars. Hence they developed the 351W, but even from its inception, Ford appreciated that while the 351W gave the capacity required, it was a marginal engine from the point of view of developing more and more horsepower as the performance wars of the late sixties escalated. So Ford designed the 351C. |

|||||||||||||||

|

The 351C was designed from the top down with the major ammount of effort put into designing the best and most efficient cylinder heads that they could to allow the engine to breathe, and so to rev. |

|||||||||||||||

|

The 351C has a canted valve cylinder head, with splayed valves set at slight angles to one another, unlike the 351W which has parallel valve stems. This canted valve arrangement makes the 351C cylinder heads bigger - wider - than those of the 351W, and as a result it has wider rocker covers. As an aid to identification, the 351W exhaust manifold to cylinder head surface is almost vertical as viewed from the ends of the engine, whereas the 351C has an exhaust manifold to cylinder head surface which sits at 45 degrees and is as near parallel to the side of the block. This can be difficult to see if an engine is in place. |

|||||||||||||||

|

So, the other easy means of 351W to 351C differentiation is to know that the 351C has a dry inlet manifold wherein cooling water does not pass from head to head through a passage in the manifold, but instead passes across the engine in a cast extension to the front of the block. This extension also provides a ‘recess’ for the timing chain and contains the thermostat housing. Simply put, the top radiator hose for a 351C goes vertically into the thermostat on top of this extension, and the 351W top radiator hose goes in horizontally to its thermostat as fitted to the front of the inlet manifold. |

|||||||||||||||

|

Okay, that was the easy part. Now we can look at different versions of the 351C. It is best to start out by describing how the Cleveland was designed for the Americans, before moving on to the Australians. Ford U.S. came up with two basic versions of their 351C, the 2V and the 4V. The 2V stands for, as it does most usually, 2 venturis, and describes a two barrelled carburettor. American 2V 351Clevelands came equipped with two barrelled carbs and as such the engine was designed to be the common version of the engine fitted to non performance cars. To this end, Ford U.S. designed a set of heads for the 2V that had smaller inlet and exhaust ports to promote better low down torque. These small port 2V heads required their own inlet and exhaust manifolds to mate up with the heads and they also had smaller valves. Initial rating of the 2V engine was 250hp. |

|||||||||||||||

|

The 4V was the performance version of the 351C, and was so named because it was designed to have a 4 venturi or four barrelled carburettor. To feed the extra fuel through the cylinders, the 4V heads had much larger ports than the 2V, and as result required their own matching inlet and exhaust manifolds, and larger valves. The combination of bigger, more effective 4 barrel carburettor, bigger valves and bigger ports ensured that the fuel mixture could get into and the exhaust gasses get out of the combustion chamber more effectively than in the 2V heads, hence the 4V engine would rev better and as a consequence, produce more power. The 351C 4V was rated, in 1970, at 300hp. |

|||||||||||||||

|

Engineering is often a compromise, and such was the case with the 4V. The valves, and especially the ports were so big that the inlet mixture could slow down in its passage into the combustion chamber. This decrease in velocity, most noticable at low revs, left the 4V versions of the 351C feeling kind of sluggish as the cylinders struggled to fill. The 2V, with its smaller ports and valves, could keep the mixture velocity up which promoted better cylinder filling, and gave the 2V its impression of greater low down power, torque and flexibility. Of course, this is what Ford U.S. wanted, promoting the 2V as the torquey grocery getter engine, and the 4V as the “let it rev and feel the power” engine. |

|||||||||||||||

|

In the U.S. for the very brief period that the musclecar/horsepower craze continued during the 351C’s early life, the 4V spawned a small clutch of developments:- the 1971 Boss 351; the 351CobraJets, or CJs; and four bolt mains caps. These were U.S. only developments and never made it to the Australian chapter of the 351C story to which we now turn. |

|||||||||||||||

|

The first 351C engines to appear in an Australian Ford were those fitted to the XW GT Phase 1.5s built in February, 1970. The U.S. 351C was announced for the 1970 model year and introduced in September, 1969, so it took less than six months for the Cleveland to appear in Australia. The Phase 1.5 - one and a half - was to all intents and purposes an XW GTHO with all the running gear from the 351 Windsor powered Phase1 but with an imported 351C 4V engines fitted. They were cars to tide the market over until the full production Cleveland powered XW GTs were released in April, 1970. The regular production XWGT, powered by the 351C, then ran out the XW model to October, 1970. Later, introduced in June, 1970, was the XW GTHO Phase2 fitted with the U.S. imported 351C engine which had a solid lifter camshaft, and a 780cfm Holley carburettor. You can see that the 351C was regarded first and foremost as its flagship engine. |

|||||||||||||||

|

With the October, 1970 introduction of the XY Falcon and ZD Fairmont range of cars, the Cleveland progressed beyond its performance image and 250hp, two barrel carburetored, 2V versions were offered as the top option on both models. The 300hp, four barrelled, 4V version of the engine was only offered on the XY GT and GTHO. Both these engines were still imported, but Ford Australia was keen to build its own and had tooled up to provide locally manfactured 351C and 302C engines. Why tool for a 302C engine when they had been using the 302W ? Well, it provided economies of scale, being able to use all of the ancilliary parts from one engine on another, and all for the sake of a different crank and rods. |

|||||||||||||||

|

And so the March, 1972 introduction of the Australian designed XA Falcon range also saw the debut of Australian built 351C and 302C in two barrel carbed, 2V form. There have been some reports that 302C’s were fitted to Brisbane built, December, 1971 XY Falcons. Brisbane cars have the letter ‘H’ as the second leter of their VIN. For the moment, the four barrel, 4V engines were imported, but by the early/middle of 1973 Ford Australia had developed their own four barrel fed 351C but used their own 2V style heads on the engine. |

|||||||||||||||

|

This is where the 2V and 4V descriptive terms become somewhat entwined. The distinct separation that applied in the U.S. between 2V and 4V ensured that a 2V Cleveland had a two barrel carb and inlet manifold, small inlet and exhaust ports and an enlarged chamber volume, while the 4V Cleveland had a four barrel carb, large inlet and exhaust ports and reduced size chamber volume which created a higher compression ratio. Now the Australians introduced a 2V head that took either a two or a four barrel carb inlet manifold, and had a large, but not as large as the U.S. 2V, open chamber size, plus, for further confusion, they introduced a 302C engine that had 2V heads which had a two barrel carb but a chamber volume smaller than anything the U.S. had offered, even on their highest performance Clevelands. |

|||||||||||||||

|

While the home grown four barrel, 2V 351C was introduced on automatic XA GTs towards the end of its life, the last of the imported, high compression, big port, 4V U.S. engines lasted only through to the first few months of XB GT production, again mostly, but not exclusively, in manual transmission cars, and by January, 1974, they were gone and all 351C engines that followed were Australian made. |

|||||||||||||||

|

The 351C ran through till the middle of the XE Falcon’s life before, to howls of protest, Ford killed off their V8 in 1982. In its later life it suffered compression ratio cuts, emissions equipment additions and a swap to Carter carbs to keep it clean and healthy, but, it started out as a romper stomper, so let’s look at its glory days, and hopefully explain some of the mysteries and anomalies. |

|||||||||||||||

|

We will start not quite at the beginning because I do not have a photo of a XW GTHO Phase 1.5, but with a Phase2. |

|||||||||||||||

|

|||||||||||||||

|

Pretty impressive, but what do we look for ? |

|||||||||||||||

|

The first 351C’s were all imported from the U.S. and as such conform to how the Americans were building and tooling for their engines. So, firstly, Ford had a policy of giving their engines an engine code number. This should not be confused with the practice of assigning an engine code letter to the vehicle’s data plate or VIN. For example, 351C’s with four barrel carb’s fitted to GT’s used the letter ‘T’ on the compliance plate. The engine code number was a number assigned to a production batch of engines and is used to describe the engine in some detail, especially if it is used to identify the engine to a parts counter. |

|||||||||||||||

|

U.S. 351C’s used a code system that started with the letter ‘K’, and followed it with a sequential set of numbers running from 600 to 632. For example, ‘K625’ was the Boss351, and ‘K610’ was a ‘M’ letter code, 351 2V engine. I will not run through the whole list of U.S. engines, but instead concentrate on those that reached Australia. These were:- |

|

K601, K604 and K614 which were 2V, two barrel carb engines as fitted to XY Falcons and ZD Fairlanes. |

|||||||||||||||||||||||||||||||||||||

|

K608 and K609 which were 4V, four barrel carb engines fitted to XW and XYs. |

|||||||||||||||||||||||||||||||||||||

|

K616 and K617 which were 4V, four barrel carb engines fitted to XA and early XBs. |

|||||||||||||||||||||||||||||||||||||

|

Originally in the U.S. this number was on a metal tag that was attached to an ancilliary bracket or more usually sandwiched under the coil mounting bracket, but later in life they were reduced to a white paper sticker on the front of the right hand valve cover. The 351C’s built in the U.S. and shipped for export acquired the letter ‘C’ in front of the ‘K’ and became CK601, CK604, CK608, CK609, CK614, CK616 and CK617, and this is what appeared on the paper tag on engines fitted in Australia. This ‘C’ stood for ‘Canada’ as engines built for Canada could be exported to Australia without Australia paying import duty, as both were Commonwealth countries. The ‘CK’ engines are identical to their US counterparts. It is also worth mentioning that in the US the switch from using a metal tag to a paper decal took place in Februay, 1973, yet the paper decals were appearing on Australian engines before that. |

|||||||||||||||||||||||||||||||||||||

|

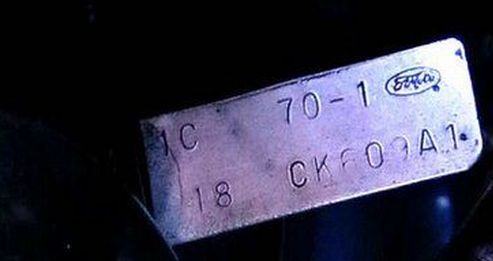

Here is an example of a coil tag that was fitted to an XA GT RPO83. |

|||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||

|

What is interesting about this tag is that XA GT RPO’s were built in August, 1973. The tag decodes as - ‘351C’, the engine; ‘72’, the model year; ‘5’, the change level or version; ‘G26’, 26th of July assembly date; and ‘CK617J1’, the engine code. On U.S. tags there is usually a digit in front of the ‘G26’ which signifies the year of production. The year is missing on this Australian or export tag which may have been a a deliberate policy to allow Ford to stockpile export engines, either in the U.S. or at their destination. |

|||||||||||||||||||||||||||||||||||||

|

It is also worth mentioning that the equivalent paper tag for this engine reads ‘CK617J1-W’ and it signifies a special order, manual transmission only square block import engine with big port heads. Some more of what this means is explained below. |

|||||||||||||||||||||||||||||||||||||

|

Here is an example of the paper tag for a ‘CK608’ engine, showing its location. |

|||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||

|

As these paper tags appear in several of the following pictures, here is a breakdown of their significance: |

|||||||||||||||||||||||||||||||||||||

|

CK608 A1 70-1 - manual D block 4 heads (XW-XA) |

|||||||||||||||||||||||||||||||||||||

|

CK609 A1 70-1 - auto D block 4 heads (XW-XA) |

|||||||||||||||||||||||||||||||||||||

|

CK616 J1 71-3 - auto D block 4 dot heads |

|||||||||||||||||||||||||||||||||||||

|

CK616 J3 72-5 - auto D block 4 dot heads (1971 casting |

|||||||||||||||||||||||||||||||||||||

|

CK616 J3 72-5 - auto square block 4 dot heads (1972 casting) |

|||||||||||||||||||||||||||||||||||||

|

CK617 J1 71-3 - manual D block 4 dot heads |

|||||||||||||||||||||||||||||||||||||

|

CK617 J1 72-5 - manual square block 4 dot heads |

|||||||||||||||||||||||||||||||||||||

|

CK617 J1W 72-5 - manual square block 4 dot heads |

|||||||||||||||||||||||||||||||||||||

|

Some of what the descriptions mean will be explained below. |

|||||||||||||||||||||||||||||||||||||

|

Regarding coil tags, and by way of comparison to the previous one, here is the tag for an early XY GT. |

|||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||

|

This shows that it is a:- ‘351C’, engine; ‘70’, model year; ‘1’, first version; ‘A18’, 18th of January engine build; and ‘CK609A1’ engine code. This is a ‘D’ block code. |

|||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||

|

As a check, here is the block from that engine showing the casting numbers:- ‘DOAE-J’, is the ‘D’ block casting and - not too well reproduced - under it is the casting date, ‘9M13’, 13th of December, 1969. |

|||||||||||||||||||||||||||||||||||||

|

It was mentioned above that in the US they changed to engine code stickers in February, 1973. This is what they looked like, and note they were on the drivers side - in Australian terms - front face of the rocker coverand not the pax side. |

|||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||

|

Back to contents |

|||||||||||||||||||||||||||||||||||||

|

‘D’ block or the ‘square’ block |

|||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||

|

The terms ‘D’ block and ‘square’ block apply to differences in the casting of the engine block. The ‘D’ block is the earlier casting, in fact the initial casting of the 351C block and the ‘square’ block is the later one. How much later is open to conjecture. ‘Square’ blocks would appear to have been available in the U.S. in 1971, and there is some evidence to show that the ‘square’ block appeared in automatic XY 351C 2V’s as early as May, 1971, and in manual XY 351C 2V’s in December, 1971. It does appear that XY 351C 4V engines continued with ‘D’ blocks. What can be said though is that no XW or XY GT came with a square block, and that all Australian built engines are patterned after the ‘square’ blocks. |

|

The ‘D’ |

|

||

|

|

||

|

The ‘D’ can be seen on the cast extension on the front of the block, adjacent to the petrol pipe. |

|

To fit 351C engines, it is generally accepted that there are seven types of production Cleveland heads that you may come across, five U.S. and two Australian. They are:- |

|

U.S. 4V Closed chamber with a ‘4’ cast in the corner |

|||||||||||||||||||

|

U.S. 4V Open chamber with a ‘4’ cast in the corner |

|||||||||||||||||||

|

U.S. 4V Closed chamber with a ‘4’ and a ‘dot’ cast in the corner |

|||||||||||||||||||

|

U.S. 2V Open chamber with a ‘2’ cast in the corner |

|||||||||||||||||||

|

U.S. 2V Open chamber with a ‘2’ and a ‘dot’ cast in the corner |

|||||||||||||||||||

|

Aus 2V Open chamber with nothing cast in the corner as fitted to Aus 351C |

|||||||||||||||||||

|

Aus 2V Closed chamber with nothing cast in the corner as fitted to Aus 302C |

|||||||||||||||||||

|

To take them in turn. |

|||||||||||||||||||

|

The U.S. 4V closed chamber head with the ‘4’ casting is the head fitted to the CK608 and CK609 engines installed in XW and XY GT’s. These heads were fitted to imported ‘D’ block engines. |

|||||||||||||||||||

|

The U.S. 4V open chamber head was not fitted to any Australian Ford. |

|||||||||||||||||||

|

The U.S. 4V closed chamber head with the ‘4’ and ‘dot’ casting is the head fitted to the CK617 engines installed from mid 1972 XA through to end of 1973 XB manual transmission equipped GT’s. It has a slightly larger chamber than the ‘4’ only casting with a resultant half a point compression drop in C.R. These engines were imported ‘square’ block engines. |

|||||||||||||||||||

|

The U.S. 2V open chamber head with the ‘2’ casting is the head used on the CK601 and CK604 engines in XY’s and ZD’s. These were imported ‘D’ block engines. |

|||||||||||||||||||

|

The U.S. 2V open chamber heads with the ‘2’ and ‘dot’ casting in the head were used on the CK614 engines fitted to late XY’s and ZD’s. These engines were imported ‘square’ block engines. |

|||||||||||||||||||

|

The Aus 2V open chamber head with no casting mark is the head fitted to Australian built 351C’s fitted to XA’s through to XE’s with both four barrel and two barrel carbs. |

|||||||||||||||||||

|

The Aus 2V closed chamber head with no casting mark is the head fitted to Australian built 302C’s fitted to XA’s to XE’s with two barrel and four barrel carbs. It has the smallest chamber size of any of the production Cleveland heads. |

|||||||||||||||||||

|

So where are the cast marks ? |

|||||||||||||||||||

|

|||||||||||||||||||

|

If they are present, they are in the top corners of the cylinder heads, visible because the rocker cover has its corner angled. In the photos above and below, you can see the ‘4’. These are XW GT’s. |

|||||||||||||||||||

|

|||||||||||||||||||

|

And the ‘4 dot’ ? |

|||||||||||||||||||

|

|||||||||||||||||||

|

|||||||||||||||||||

|

As fitted to XA’s. |

|||||||||||||||||||

|

And so to put some of this in context. |

|||||||||||||||||||

|

|||||||||||||||||||

|

Here is an XY GTHO. |

|||||||||||||||||||

|

|||||||||||||||||||

|

And here are the features we have discused so far:- CK608, ‘D’ block and ‘4’ cylinder heads. |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Here is an XA GT. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

CK617, ‘square’ block and ‘4dot’. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

There are, of course, some strange anomalies. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

This is a July,1972 XA GT. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

It has a ‘D’ block and ‘4’ heads. A leftover from the XY perhaps. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Here is another, showing an original factory rocker cover sticker in place. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Later Australian 351C’s, like this 1974 XB GT, had Australian ‘square’ blocks and Australian cylinder heads with no casting mark. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Note this June, 1974 XB GT has the the third type, or Australian, rockers covers, as described later, and the location of the engine/VIN stamping on the block - on the vertical face of the timing chain block extension.. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

This 351C in a September, 1973 LTD Landau also has the Australian style open chamber heads with nothing cast in the corner. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

By way of comparison, and as an aside, here is a U.S. 351C 2V engine in a 1973 Mercury Cougar convertible. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Note that it has a completely different air cleaner as that fitted to 4V and 2V Australian engines, whether two barrel or four barrel equipped. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Shown here in close up is the square block of the Cougar and the ‘2 dot’ heads. In Australia, these heads were only fitted to late, two barrelled XYs and ZDs. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Back to contents |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Rocker Covers |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

This is an original XY GT with a ‘D’ block and the ‘first’ style rocker covers with the small dimple in the closest corner of the cover. These rocker covers were supplied on all of the imported ‘D’ block 351C’s, whether they were 4V or 2V. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

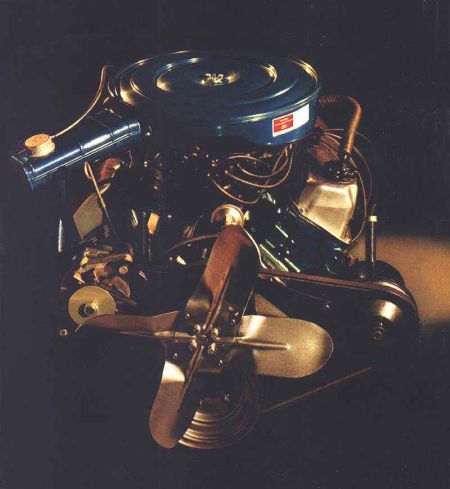

A 351C 2V from the ZD fairlane brochure. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The ‘second’ style rocker cover was introduced with the ‘square’ block and it has a much more pronounced chamfer to the front corner. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

While it is generally accepted as a rule of thumb that it was only the ‘square blocks that had this cover, there is some evidence to show that a few ‘D’ blocks also were fitted with these ‘second’ type rocker covers. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

When Australian manufacture of the 351C started, this was the rocker cover that they initially produced. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

There is another subtle external difference to the rocker covers as fitted to ‘D’ blocks, and U.S. and Australian ‘square’ blocks. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The ‘first’ type, dimpled cover has the ‘Power by Ford’ logo enclosed in a ribbed box which has larger rounded corners as shown above. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Whereas the ‘second’, chamfered cover has a much tighter, almost square corner to the surrounding ribbed box. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

However, it seems that the ‘second’ Cleveland type, the chamfered corner rocker cover also came with the larger, rounded corner edge to the raised box around the ‘Powered by Ford’ stamping. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

This can be seen on these two 1972 Ford Gran Torino Sports that were exported new to the U.K. On this 351 2V engine. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

And on this 351CJ version. Note the ‘4 dot’ heads. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Later Australian covers, fitted to later XB’s manual trans equipped cars, most automatic equipped XB’s and all XC’s dispensed with the ‘Power by Ford’ and only had the ‘Ford’ logo. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

This, below, one is from a 1973 Landau. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

These rocker covers also appeared on 351 Clevelands fitted to 1973 U.S. Torinos. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Here are a few interesting photos showing the difference between a U.S. ‘chamfered’ set of 351C rocker covers that feature the rounded ‘PbF’ rib - as seen on the 72 Torino above - and in comparison with a set of Australian 302C rocker covers. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

It can be seen that the shape of the ‘chamfered box’ that supports the pcv valve hole is completely different to that of the U.S. rocker cover, and by extension, the covers fitted to early Australian 351 engines. The upper flat surface is smaller and the two ‘chamfers’ are much more pronounced. It is also worth noting that the U.S. 73 Torino immediately above has the U.S. style ‘chamfer’ box, but a ‘Ford’ only stamping, implying that the U.S. ‘Ford’ only rocker cover was different from the Australian one. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Back to contents |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Air Cleaners |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Air cleaners fitted to 351C’s are another area where there should be hard and fast rules, but there appear to be some strange variations. Here is what I think holds true. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

351Cleveland powered XW GT’s came with an open element air cleaner, whether the car was equipped with a manual transmission or an automatic. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

And the air cleaner read ‘351 High Performance’. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

XY GT and GTHO’s had the shaker air cleaner fitted to their 351C’s. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

GTHO’s did not have a snorkel. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Note the support bracket and nut for the air cleaner. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

And as fitted to non-HO XY GT’s, the air cleaner had a snorkel. This shape of snorkel, with the belled end, is correct for XY Falcons. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

ZD Fairlanes used the same air cleaner base as XY’s but with the top used on the earlier 351Windsor engines in XW GT’s and ZC Fairlanes. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

And XY 351C 2V Falcons used the same air cleaner. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

This is the XY shaker air cleaner with shaker removed. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

XY 351’s, both two barrel and in non-HO GT guise came with provision for the small hole steel heat riser tube which can be seen in some of the photos above, but is easily seen in the photo below. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

This contrasts with the later air cleaners which had provision for the larger concertina type of heat riser, but which does not seem to have been fited to many -if any - XA and XB cars. This is in stark contrast to the Cleveland fitted in cars sold in in the U.S. where the concertina pipe was extensively fitted due to their tighter emissions laws. This is shown in this photo of a 351C in a 1971 Mustang. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

This is the early XA air cleaner with belled end, a carryover from the XY, what we could call, the ‘first’ type. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

And later XA’s, most usually those from 1973 with twin compliance plates, used the same air cleaner but with a straight mouthed snorkel, which we could call the ‘second’ type. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

This air cleaner carried over to the XB. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

This ‘second’ type, introduced for 1973, superficially appears to be the same as that used on 1973 US 351C-4V engines, but a look at these photos shows that, in comparison with the XB air cleaner immediately above, there are some noticable differences. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

And the US 1973 351C-2V adopted a completely different air cleaner. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Just when you think things are going well with all this stuff, something comes along that throws a little curve, or in this case ‘crease’ into the mix. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

In the above you will notice that we say the XY and early XA’s had a belled end to their snorkel. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

And that later XA’s and XB’s had a straight end snorkel. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Note that this snorkel has an angled ‘crease’ just above the vacuum actuator. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

From observation, it now appears that, most probably on some late XA’s and eearly XB’s, Ford in Australia used a straight end snorkel that did not have the angled ‘crease’. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The non creased snorkel is also seen in early XB’s. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Yet another ‘strange’ Ford Australia anomaly. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

However, the non creased end is very similar to that used on U.S. 1973 4V Cleveland equipped Mustangs (as seen in photos just above) although the attachment to the air cleaner is different, being much longer and more angled downwards. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Thanks to members of the Falcon XA GT Forum for pointing this out. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

In mid 1975, with the introduction of the ADR27A emissions controls, and the inclusion of a charcoal canister, XB’s swapped to an air cleaner with a subtly different base, having a double hump arrangement to the distributor relief, as seen below. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

XC cars, as seen on this Cobra, had yet another air cleaner - the third type - with a distinctive tapered snorkel. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

But the engine size was now metricised, as below. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

XD and XE Falcons fitted with the metricised 5.8 litre engine had their own unique design of air cleaner. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Here is the red displacement graphic on the XD-XE air cleaner. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

It is worth pointing out too, that from the XW to the XC, all of the Cleveland engines had their blocks painted dark Ford Corporate Blue. Four barrel equipped cars also had their rocker covers painted Ford Blue - as seen in most of the photos above - but two barrel carb’d 351C’s as fitted to XA and XB’s had their rocker covers painted orange, as seen below. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The XD and XE engine, both 302C and 351C had black painted blocks and silver rocker covers and air cleaners. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

While it could be easy to dismiss the later Clevelands as fitted to XD and XE’s as mere shadows of their former selves, and not worth much merit, we actually find that they can throw up as much controversy as the earlier U.S. versus Australian engines, or 4V versus 2V. Welcome to the world of ‘NASCAR’ blocks and ‘pillow’ blocks. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The NASCAR blocks |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

If my understanding is correct, as the U.S. had long ceased production of Clevelands and they were very keen to still use them in NASCAR racing, they approached Ford Australia and asked them to cast up a series of blocks which had additional metal in them, which would allow some extra machining of the block, specifically some over-boring. In standard form the Cleveland was a thin wall casting which limited its over-bore capability. By casting in extra metal, there was a hope that some jiggery-pokery could be achieved. These blocks carried the casting number XE192540. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

There appears to be little correlation between the XE in the cast number and the XE Falcon model except that the two appeared concurrently on the scene. Apart from thicker bore walls, the XE blocks had thicker pan rails. Unfortunately, there was a problem and the casts suffered from core shift, to such an extent that Ford U.S. rejected them as unsuitable and left Ford Australia with them. Now Ford Australia, never being ones to miss an opportunity simply used the blocks and stuck them into passenger cars and trucks where the core shift problem was not noticable under normal driving conditions. These blocks have acquired some mythical status, but some accounts show that, as proved by Ford U.S, while the extra metal may be handy, actually benefitting from its presence while building a hi-po engine can be problematic. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The ‘Pillow’ blocks |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The pillow block was used in XD and XE Falcon/Fairmonts and came about due to a perceived need to increase the cooling capacity and capability of the Cleveland block. It was felt that as more and more cars were fitted with accesories, and specifically air-conditioning, it would be better to make some modifications to the block. These took the form of adding bulges, or pillows, to the casts to allow extra water jacket capacity. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

There again seems to be some doubt about the provance of the ‘pillow’ block. Was it fitted to XD and XE’s ? Was it restricted to air-con cars only ? Was it just used on F100 trucks ? |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

We do know that the ‘pillow’ block was fitted to some XE ESP cars, built as 302C’s. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

That the ‘pillow’ blocks were not the same as the ‘NASCAR’ blocks is shown by the fact they use the standard casting/part number as the normal blocks, as shown here. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The casting date shows as 1st, April, 1982. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Many thanks to the folk of FordForums and ESPGhia.com who have discussed this particular subject at length and from whom I gleaned the small bits of information and photographs presented above. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Back to contents |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

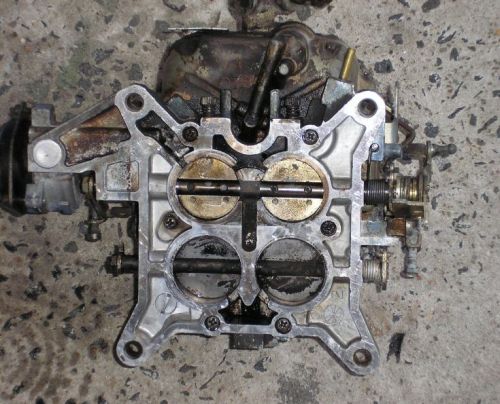

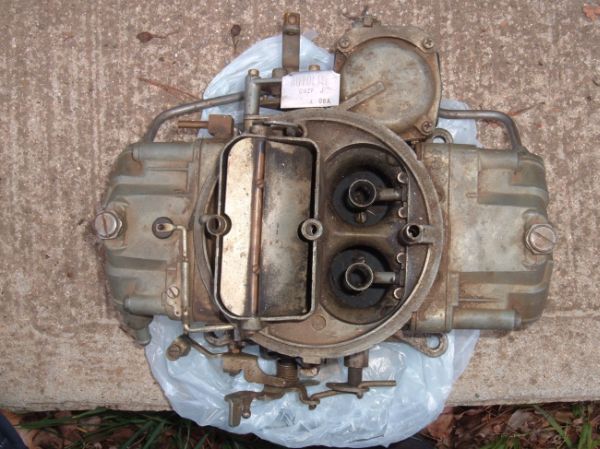

Autolite 4300 carburettor |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Most four barrel equipped Fords, up until the XC range, and excluding some of the HO or Phase cars, were fitted with Ford’s own Autolite 4300 carburettor. There are conflicting opinions regarding this carb, but it is now generally accepted to have been a far better carb than most Holley-holics ever gave it credit for. Here are a couple of photos. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Note the Autolite tag on both carbs at the front attached by one of the carb top screws, and the vertical heat shield for the choke heat mechanism; parts that can easily get lost over the years. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The exception was the XW GT which was fitted with an open element air cleaner, and the choke heat shield wasn’t fitted. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

A refurbished 1973 Autolite carb. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

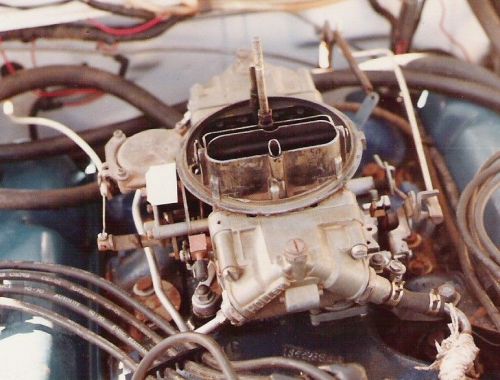

Holley carbs |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

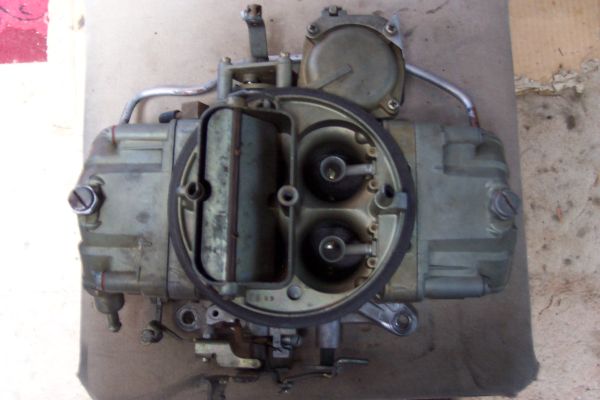

The Phase cars - XW Phase1.5 and Phase2 and XY Phase3 - were fitted with four barrel Holley carbs as seen here. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Despite some literature comments to the contrary, all three of the Cleveland engined Phase car - 1.5, 2, and 3 - were fitted with 780cfm Holley carburetors. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The Phase 1.5 and Phase2 cars had a Holley carb with the Ford part number C9ZF-9501J, with a Holley list number of 4511. This is the carb from the 1969 Boss 302 engine. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

A couple of points worth noting on these carburetors:- the location of the tag, and the vent valve on the primary fuel bowl. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

And the manual choke arrangement. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

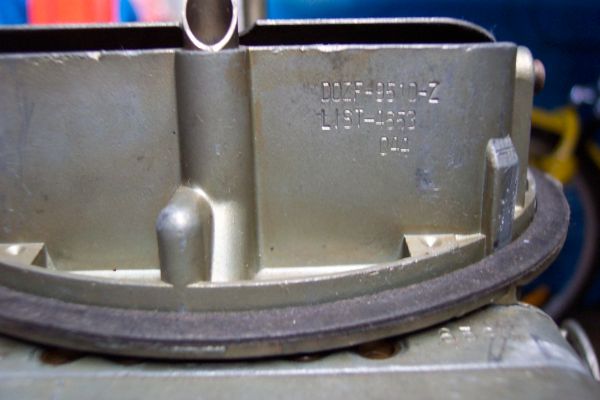

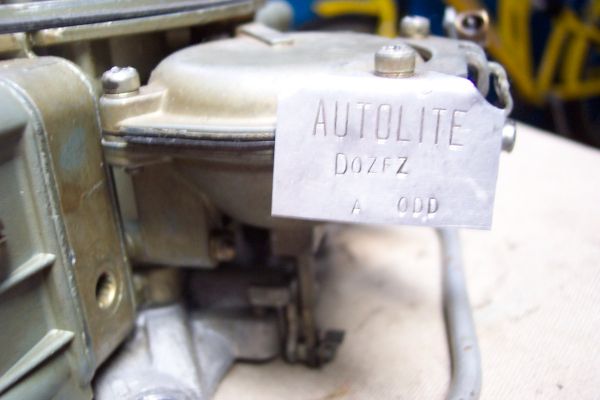

The Phase3 cars used a Holley carburetor with Ford part number D0ZF-9510-Z, with a Holley list number of 4653. This was the carb from the 1970 Boss 302 engine. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Note the different location of the tag. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Use of the Holley carb on the engines required the use of a spacer plate with vacuum take-off for the brakes. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Back to contents |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The Infamous ‘Winged’ Sump |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

There is a whole controversy of comment and conspiracy about the infamous winged sump, and what it was fitted to. To the best of my knowledge it was originally designed by Ford to be fitted to the XA Phase4, as an attempt to help some of the oiling problems that cropped up when Ford racers began racing the XA Falcons under Group C rules. With the allowance of bigger, and hence grippier, tyres it was found that the oil in the sump was sloshing about too much, and the pump pickup was being exposed. As a solution, and also to get more oil into the sump, Ford came up with the winged sump, as shown. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

With the cancellation of the Phase4, Ford still wanted to be able to use the winged sump in their race cars, but had to prove it was a factory part, so they fitted them to production cars. This fitment appears to have been a bit hit and miss, as popular speculation says they were not just fitted to GT’s, but also to ordinary 351-equipped Falcons, and even F100 pickups. What can be stated as fact is that the winged sump was not part of the RPO83 option, as fitted to late - August/September, 1973 - XA GT’s. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Here is the original ‘4 dot’ headed, square block, CK617 engine being removed from an RPO83 car. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

No wings. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The RPO83 cars did come from the factory with the same headers/extractors that had been developed for the Phase4 cars. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

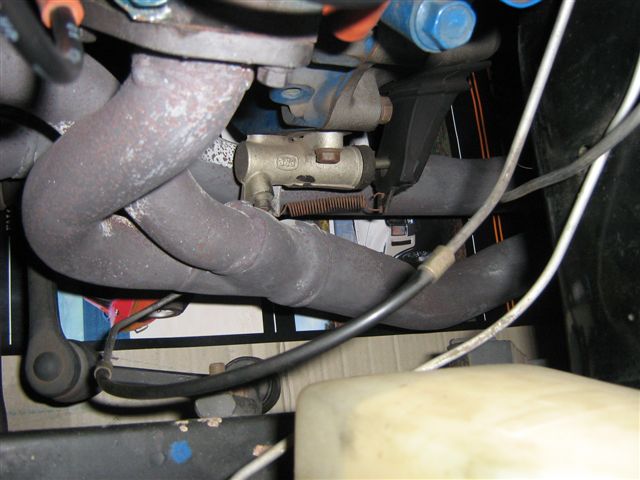

One side effect of headers/extractors being fitted to the cars was a different clutch line that was required to clear the headers. This used a flexible pipe and a longer lower section attached to the slave cylinder. This lower steel section actually passes between the two branches of the Tri-Y, as seen below. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The Phase4, and Phase3, headers/extractors were made by HM. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

When other header/extractor manufacturers came along, their fitment on manual caused some problems with the slave cylinder and the hydrualic pipe connection to it. The solution was to mount the slave cylinder 180 degrees out in rotation and use spacers to space it out. Compare the orientation of the cylinder below - pictured from underneath - with that in the photo above. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

This allows the hydraulic line, with the aid of a flexible pipe, to approach the cylinder from away from the header/extractor. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Extra pipes on my engine ? |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

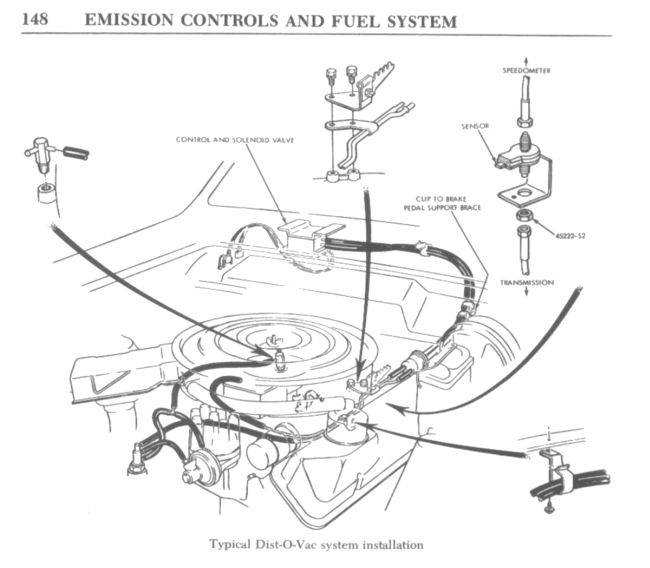

Owners of XW, XY and some XA’s may notice that they have some extra, unconnected steel pipes on their engines, running down the side of the passenger rocker cover on CK609 engines. These were early U.S. sourced Clevelands for automatic trans equipped cars. The ‘0’ in the CK609 shows that they were configured for the 1970 U.S. model year. Bear in mnd that this actually means from late July, 1969 until August, 1970. As these were high compression engines, they needed some help to pass the 1969 U.S. emissions laws. This help was known as Dist-O-Vac. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Below is a sketch of the Dist-O-Vac system. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

The Dist-O-Vac system relied on a module under the dash which combined a signal of vehicle speed and ambient air temperature to allow the passage of carb vacuum to the distributor. In the photo above, the black pipes can be seen clearly, but for a short distance alongside the rocker cover and passing the carb, they used steel pipes. |

|

On the Australian supplied CK609 engines, there was no requirement for any emissions equipment. However, it was easier for the U.S. engine factory just to allow the engines to go down the line and have the pipes fitted. It was just a case of not bothering to connect them to anything, and have the Australian factory connect up their own vacuum lines and ignore these pipes. |

|

|

Here is a CK609 engine, actually fitted to a South African Fairmont GT. |

|

|

|

And the unused pipe ends in close up. |

|

|

And another couple of blow ups of another engine. |

|

|

|

Back to contents |

|||

|

[Australian Ford Register UK] [History] [The Cars] [Members] [Bits and Pieces] [Contents] [Model Changes - Dashes] [Vinyl Roofs] [Doorhandles - Tail lamps - Glass] [Underneath] [Underneath 2] [Thorn Red] [Spoilers - Horn Cars] [Styling - Bonnets] [Grand Sports] [Metricification] [Grand Sport details - P5 LTD] [Scoops and vents] [Wheels] [The other XR8 - P6 LTD] [Superbird] [Compliance Plates] [Engines] [Engines2] [Rust] [Stampings] [Falcons] [Literature] [Some UK background] [One owner] [Bits and Pieces 2] [Untitled124] [Links] [Visitors] [Events] [AusCCA] [Site History] |