|

|

|

And the wheel would have a hard cover. Note the prominent tail-light housings on the XA hardtop due to the angled and recessed lenses. |

|

Accessed through two covered oval holes in the axle hump immediately behind the back seat braces. |

|

Back to contents |

|||||

|

The infamous Tramp Rods |

|||||

|

|||||

|

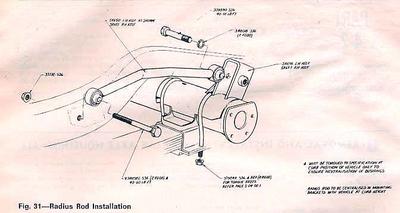

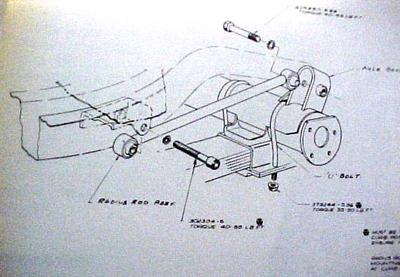

This is a rear drum braked RPO. Note the large black bracket just inboard of the drum. Bolted to the bracket, and leading forward is the ‘bent’ tramp rod and it bolts through the ‘chassis’ rail. The tramp rod was fitted to GT’s and Landau’s as an extra means of locating the axle, to stop it ‘tramping’ or bouncing up and down under violent acceleration. There were two types of attachment of the rod to the chassis. This is the later style as used on late XA GT’s and all XB GT’s and Landau’s. Early XA GT’s had another U-shaped bracket bolted to the ‘chassis’ rail, and the rod itself was straighter. Note that in the Falcon workshop manual, these rods are known as ‘radius’ rods. |

|

|

What is not too obvious from these photos is that the rods ‘stepped’ inwards from the axle to the chassis and were kinked in plan view as well as elevation to suit. |

|

|||||

|

As shown here in the blow up of the above axle photo. The rod is behind the curved handbrake cable and it can be seen that the axle mount is set further outboard than the ‘chassis’ mount so the rod kinks inwards to mate up with the ‘chassis’. Note the oiled nut and bolt shaft of the rod ‘chassis’ mount. |

|||||

|

|||||

|

Again the bar is shown here, including the means of attaching the axle end of the rod using a ‘stirrup’ which is mounted on a plate sandwiched under the axle-spring U-bolts. |

|

The later tramp rod assembly, as photographed above. |

|||

|

|||

|

Here are the parts for the later tramp bars. |

|

|||||||

|

The early tramp rod assembly, also seen below with the ‘chassis’ bracket. |

|||||||

|

|||||||

|

|||||||

|

Many thanks to the Falcon GT Club of Australia for the restored car images, Kerry who owns the red, green and yellow hardtops featured above, Terry James for the black XA and Matt for the John Goss Special. |

|

Axle and springhelpers |

|

|

While we are underneath at the axle, here is the Borg Warner axle as fitted to a 302C powered XB Fairmont hardtop. |

|

|

|

Here is the axle tag enlarged and flipped over. |

|

|

This car also has Ford’s rear spring assitors fitted. |

|

|

|

|

Back to contents |

|||

|

[Australian Ford Register UK] [History] [The Cars] [Members] [Bits and Pieces] [Contents] [Model Changes - Dashes] [Vinyl Roofs] [Doorhandles - Tail lamps - Glass] [Underneath] [Underneath 2] [Thorn Red] [Spoilers - Horn Cars] [Styling - Bonnets] [Grand Sports] [Metricification] [Grand Sport details - P5 LTD] [Scoops and vents] [Wheels] [The other XR8 - P6 LTD] [Superbird] [Compliance Plates] [Engines] [Engines2] [Rust] [Stampings] [Falcons] [Literature] [Some UK background] [One owner] [Bits and Pieces 2] [Untitled124] [Links] [Visitors] [Events] [AusCCA] [Site History] |